Introduction

Glass Reinforced Plastic (GRP) sectional water tanks have emerged as a popular choice for water storage in various applications due to their exceptional durability, flexibility, and cost-effectiveness. These tanks are constructed using panels made of GRP, a composite material that combines glass fibers with polyester resin. This article will delve into the features, benefits, applications, installation process, and maintenance of GRP sectional water tanks, providing a thorough understanding for potential buyers and users.

Durability and Strength: GRP panels are highly resistant to impact, UV radiation, and chemical corrosion. This makes GRP sectional water tanks suitable for both indoor and outdoor use, even in harsh environments.

Lightweight: Despite their strength, GRP panels are lightweight, making transportation and installation easier and more cost-effective compared to traditional materials like concrete and steel.

Modular Design: The sectional design allows for flexibility in size and shape. Panels can be assembled in various configurations to fit specific space requirements, making them ideal for both small and large-scale storage needs.

Thermal Insulation: GRP tanks provide excellent thermal insulation, helping to maintain the temperature of the stored water, which is crucial for certain applications.

Hygienic: The smooth surface of GRP panels prevents algae and bacteria growth, ensuring the water remains clean and safe for consumption. GRP tanks comply with international water storage standards.

Cost-Effective: The initial cost of GRP tanks is competitive, and their long lifespan and low maintenance requirements lead to significant savings over time.

Versatility: GRP tanks can be used in a variety of applications, including domestic, commercial, and industrial settings. They are suitable for storing potable water, rainwater, and even chemicals.

Ease of Installation: The lightweight nature and modular design of GRP tanks facilitate easy and quick installation. They can be assembled on-site, even in confined spaces, without the need for heavy machinery.

Environmentally Friendly: GRP is a sustainable material that can be recycled. The production process of GRP tanks has a lower environmental impact compared to other materials.

Customizable: GRP sectional water tanks can be customized to meet specific requirements. They can be designed to withstand specific pressures, temperatures, and environmental conditions.

Domestic Use: GRP tanks are ideal for residential water storage, providing a reliable and hygienic solution for households.

Commercial and Industrial Use: These tanks are widely used in hotels, hospitals, schools, and industrial facilities for storing large volumes of water. They are also suitable for fire protection systems.

Agricultural Use: GRP tanks can store water for irrigation, livestock, and aquaculture. Their resistance to chemicals makes them suitable for storing fertilizers and pesticides.

Municipal Use: Local authorities use GRP tanks for water supply systems, wastewater treatment, and rainwater harvesting.

Site Preparation: Ensure the installation site is level and free of debris. A concrete foundation is recommended for stability.

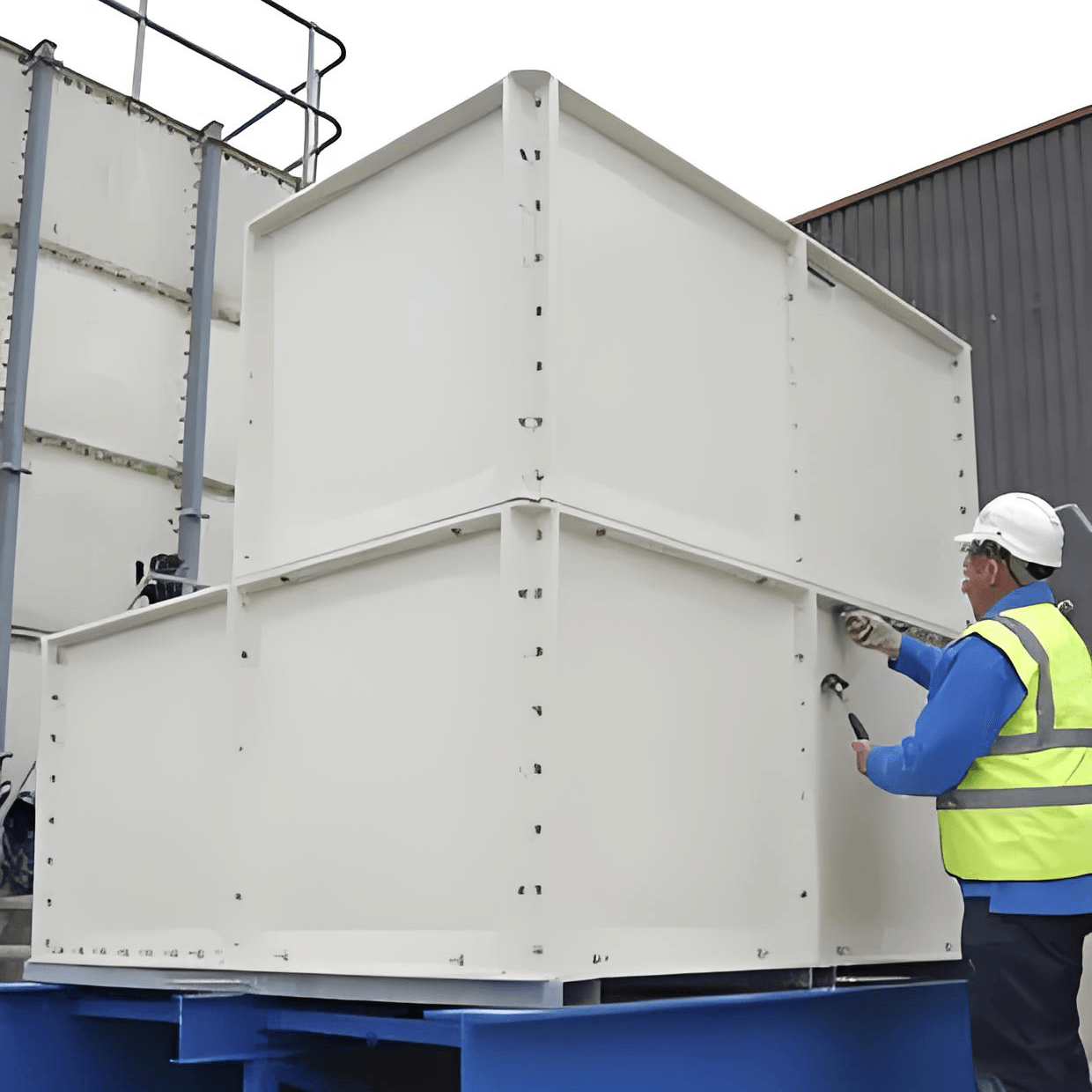

Panel Assembly: Start by assembling the base panels, followed by the side and roof panels. Secure each panel with bolts and ensure they are aligned correctly.

Sealing: Apply a sealant between panels to prevent leaks. GRP tanks often come with pre-fitted seals to simplify this process.

Fittings and Connections: Install necessary fittings, such as inlet and outlet pipes, overflow pipes, and manholes. Ensure all connections are watertight.

Testing: Once assembled, fill the tank with water and check for leaks. Conduct a pressure test if required to ensure the tank can withstand the intended pressure.

Regular Inspections: Inspect the tank periodically for signs of wear, damage, or leaks. Check the condition of the sealant and fittings.

Cleaning: Clean the interior of the tank regularly to prevent the buildup of sediments, algae, and bacteria. Use non-toxic cleaning agents to avoid contaminating the water.

Repairs: Promptly repair any damage to the panels or fittings to maintain the integrity of the tank. GRP panels can be easily repaired or replaced if necessary.

Monitoring: Install monitoring systems to keep track of water levels, temperature, and pressure. This helps in early detection of potential issues.

GRP sectional water tanks offer a robust, versatile, and cost-effective solution for water storage across various applications. Their durability, ease of installation, and low maintenance requirements make them an excellent choice for both residential and commercial use. By understanding the features, benefits, and proper maintenance of GRP tanks, users can ensure a reliable and long-lasting water storage system. Whether for household use, industrial applications, or municipal water supply, GRP sectional water tanks are a dependable option that meets modern water storage needs.

Experience the brand Trusted by Renowned Companies across the GLOBE.

Pipeco stands at the forefront of the market, recognized as a premier manufacturer, supplier, and exporter specializing in top-tier GRP water tanks, stainless steel water tanks, and SMC manhole covers, FRP Water Tank, Fiberglass Tank, SMC Water Tank committed to delivering unparalleled quality and excellence.