PIPECO GRP Sectional Water Storage Tanks' panels are manufactured using chopped fiberglass and unsaturated polyester resin under high pressure and temperature. These GRP Water Tanks are designed to meet high standards of durability and performance.

The high-quality SMC Water Tanks from PIPECO are molded using advanced technologies. Panels are formed under tonnage presses heated up to 150°C, resulting in smooth, highly resistant, and perfectly cured surfaces. This ensures that PIPECO GRP Water Tanks, including GRP Square Shape Tanks, are reliable and long-lasting.

PIPECO GRP panels are WRAS approved, meeting the highest global standards. Additionally, panels undergo stringent testing by TSE to ensure compliance with health and nutrition regulations. These GRP Water Tanks are UV stabilized, preventing algae growth inside the tank—a perfect choice for FRP Water Tanks and other applications.

PIPECO GRP panels are non-adhesive and boast a clean finish. Molded using high-temperature molds and hydraulic presses, they deliver smooth surfaces and robust structural integrity. These features make PIPECO’s GRP Sectional Tanks and SMC Water Tanks highly reliable and efficient for various applications.

Our GRP panels maintain consistent glass fiber content, ensuring uniform mechanical strength and excellent flexibility. Their smooth and elegant surface minimizes finishing requirements, making these Fiberglass Tanks a preferred choice for diverse uses.

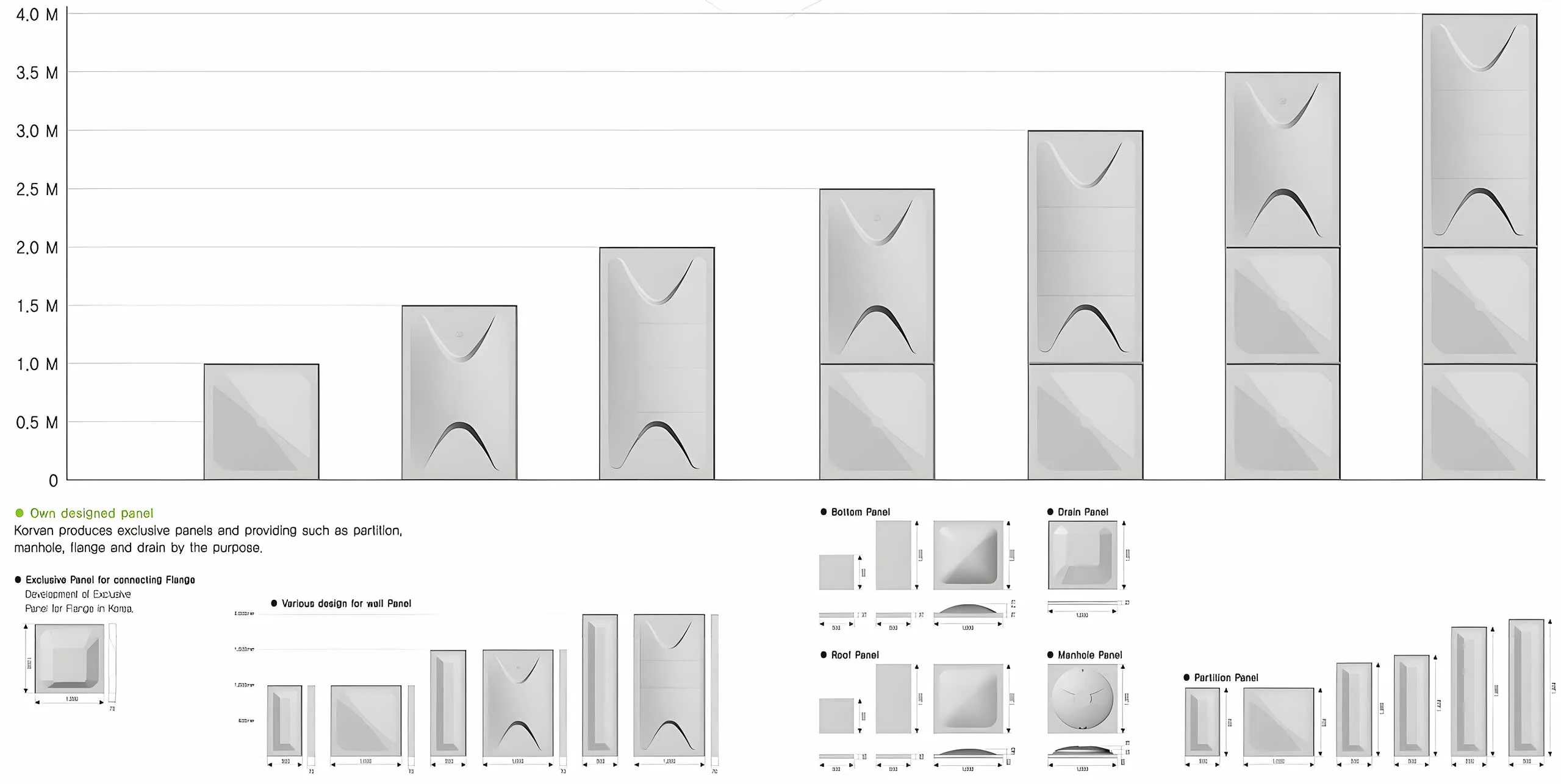

Unlike traditional FRP tanks, PIPECO GRP can easily correct deformities with ribs, bosses, and inserts. It allows for the creation of molds with varying thicknesses and exhibits exceptional mechanical strength, offering an ideal solution for GRP and SMC Water Tanks alike.

Standard : BS EN 13280:2001 and British Standard BS 7491 Part 3:1994

Materials : Sheet Moulding Compound (SMC) consists of below specification

Resin – Isophthalic unsaturated polyester resin conforming to BS 3532 specification

Fiber Glass – Low alkali fiberglass conforming to JIS R3411 to R3417 or BS 3396, BS 3496, and BS 3749 specifications.

Testing Method : BS2782

Manufacturing Process : Hot pressed SMC compression moulding ensures the high quality of our GRP Sectional Tanks and SMC Water Tanks.

Tank Structural Support : External: Hot Dipped Galvanised Steel

Internal: SS316

Roof Support: GRP Pipes

Sealant : Non-toxic PVC

Bolt, Nuts, Washers : External Standard: SS316 A4 Grade (Optional SS304)

Internal Standard: SS316 (In-contact with water)

Roof : Standard: SS316 (Optional SS304)

Ladder : External: Standard Hot Dipped Galvanised Steel, 300mm width

Internal: Standard GRP

Optional: SS 304 and 316, 300mm width

Water Level Indicator : Standard: Direct Reading Clear Tube Type

Optional: Reversed Reading Mechanical Ball Float Type (Cat & Mouse)

Nozzle Panel : Flat panels will be provided on request for these versatile Fiberglass Tanks.

External Braced System : External: Hot Dipped Galvanized Steel

Internal: None (metal-free inside, non-partitioned tank only)

Roof Support: GRP Poles

1. PIPECO’s tanks can withstand temperatures up to 150°C during manufacturing, ensuring exceptional durability.

2. GRP and SMC Water Tanks are eco-friendly, with recyclable materials and a long lifespan that reduces waste.

3. They are used in a variety of applications, from potable water storage to fire suppression systems, showcasing their versatility.

4. PIPECO’s innovative manufacturing techniques ensure seamless integration of custom features to meet unique requirements.

Experience the brand Trusted by Renowned Companies across the GLOBE.

Pipeco stands at the forefront of the market, recognized as a premier manufacturer, supplier, and exporter specializing in top-tier GRP water tanks, stainless steel water tanks, and SMC manhole covers, FRP Water Tank, Fiberglass Tank, SMC Water Tank committed to delivering unparalleled quality and excellence.