Introduction

Glass Reinforced Plastic (GRP) tanks, also known as fiberglass tanks, are increasingly popular due to their durability, lightweight, and corrosion resistance. Whether used for water storage in residential, commercial, or industrial settings, the proper installation of a GRP tank is crucial to ensure longevity and performance. This guide will walk you through the essential steps for a successful GRP tank installation, focusing on GRP water tanks, FRP water tanks, GRP sectional tanks, and GRP square shape tanks.

Understanding GRP Tanks

GRP tanks are manufactured using high-quality fiberglass and resin, making them ideal for storing various liquids, including potable water. They are often referred to as GRP water tanks, FRP water tanks (Fiberglass Reinforced Plastic), or simply fiberglass tanks. These tanks are available in different configurations, including GRP sectional tanks and GRP square shape tanks, allowing for versatile installation options.

Preparation for GRP Tank Installation

-

Site Selection: Choose a flat, stable site with sufficient space for the tank and any additional components like pipes and pumps. The site should be easily accessible for maintenance and inspections.

-

Foundation: The foundation is critical for ensuring the stability of the tank. A concrete base is often recommended, especially for large GRP sectional tanks. The foundation should be level, smooth, and strong enough to support the filled tank's weight. Check the flatness of the concrete plinth, with a tolerance of 2mm.

-

Environmental Considerations: Consider the surrounding environment, including drainage and exposure to sunlight. GRP tanks are UV-resistant, but prolonged exposure to harsh sunlight can affect the tank's appearance over time.

Installation Steps for GRP Tanks

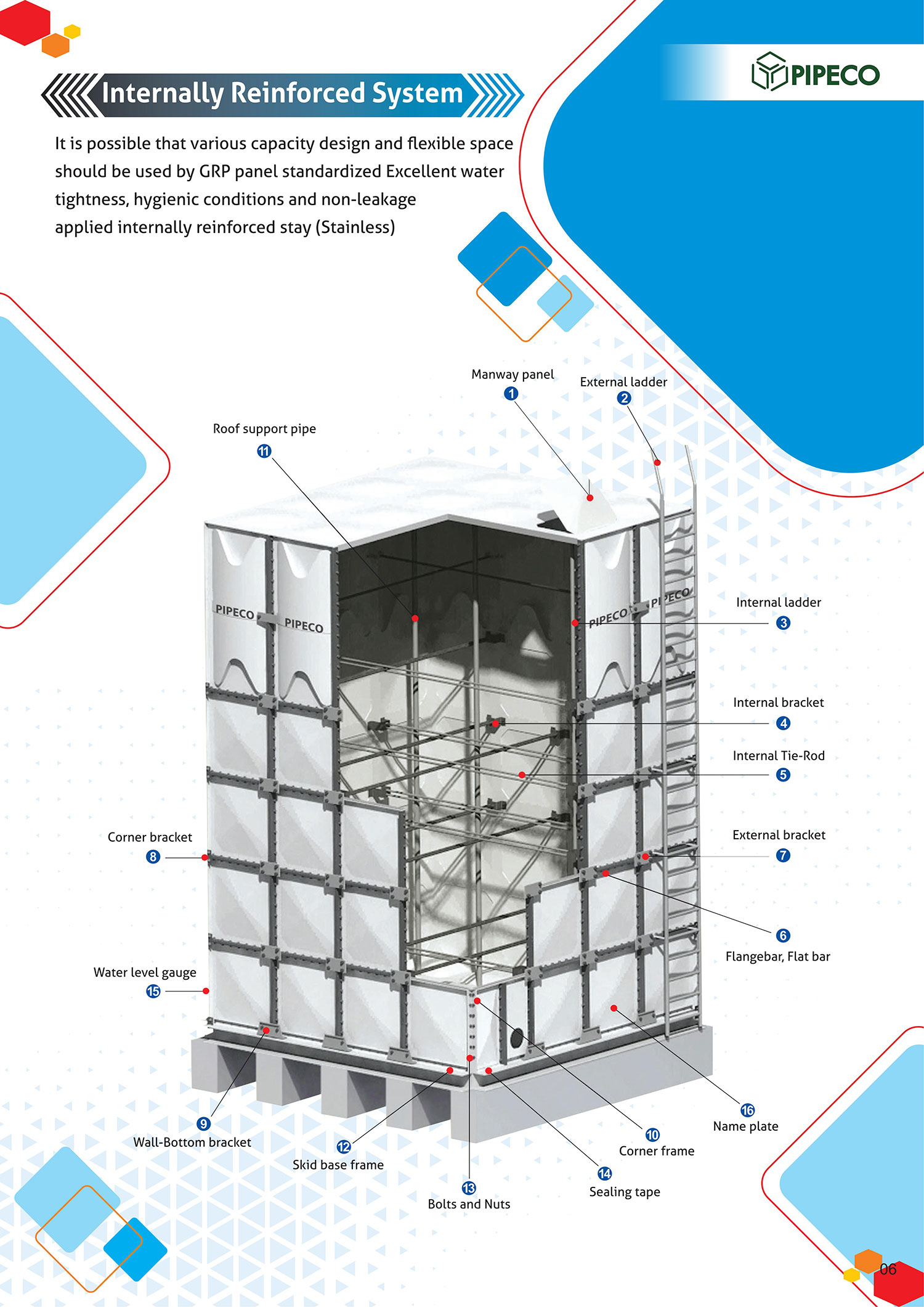

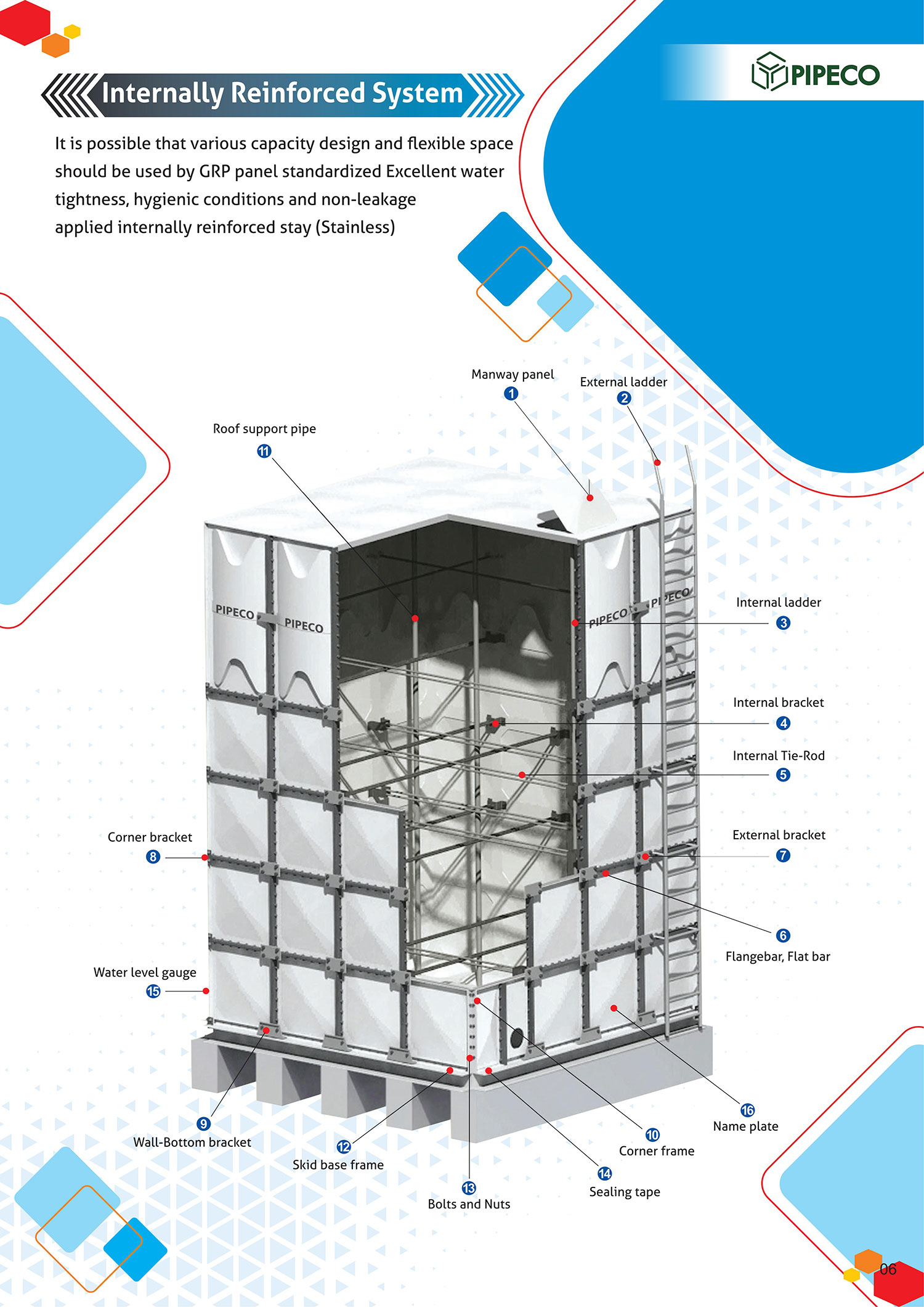

1. Assembly of GRP Sectional Tanks:

-

Panel Arrangement: GRP sectional tanks consist of panels that are bolted together on-site. Begin by arranging the base panels on the prepared foundation.

-

Bolting Panels: Securely bolt the panels together, ensuring a watertight seal using the provided gaskets. For GRP square shape tanks, the panels are often pre-fabricated and require minimal assembly.

-

Internal Bracing: Install internal bracing and stays to prevent the tank walls from bulging under pressure. This is particularly important for large-capacity tanks.

2. Pipe Connections:

-

Inlet and Outlet Pipes: Connect the inlet and outlet pipes to the appropriate ports on the tank. Ensure that all connections are sealed and leak-proof.

-

Overflow and Drainage: Install an overflow pipe to prevent overfilling and a drainage pipe for maintenance purposes.

3. Insulation and Cladding:

For installations in cold climates, consider adding insulation to prevent freezing. Cladding can be used to protect the tank from external damage and improve its aesthetic appearance.

4. Final Checks:

-

Leak Testing: After installation, perform a leak test by filling the tank with water and checking for any leaks at the joints and connections.

-

Water Level: Ensure that the water level remains above the tie rod position at all times, ideally over 85% of the tank height.

-

Ventilation: Ensure that the tank is adequately ventilated to prevent pressure build-up during filling and emptying.

Maintenance and Inspection

Regular maintenance and inspection are vital for extending the lifespan of GRP tanks. Key maintenance tasks include:

-

Cleaning: The interior of the tank should be cleaned at least twice a year. After cleaning, check whether the water quality in the tank is proper. When cleaning one compartment of the tank, ensure the water level in the other compartment is less than 50%.

-

Inspection: Inspect the tank for cracks, leaks, or any signs of wear. Pay special attention to the joints, connections, and deflection of the wall panels (which should not exceed 1% of the tank height).

-

Supports and Rods: Check all internal supports for corrosion. If corrosion is found, it should be rectified immediately. Additionally, check that all tie rods are tightened.

-

Pipe Work: Ensure that all pipes connected to the tank are suitably braced and that the structural supports under the tank are in good condition.

-

Overflow and Air Inlet Screens: Verify that overflow fittings are in place and that air inlet screens are not blocked.

-

Ladders and Seals: If ladders are fitted to the tank, ensure they are securely fastened and undamaged. During cleaning, avoid interfering with the joint seals.

-

Cleaning Agents: Do not use organic solvents, including thinner, acetone, or chlorine bleach, to clean the exterior or interior of the tank.

-

Water Storage: The tank should only store normal-temperature drinking water and should not be used for any other purpose.

Please note that Pipeco Korea will not bear responsibility for any issues arising from failure to follow these recommendations, inadequate strength or uneven concrete plinths, or natural disasters.

Advantages of GRP Tanks

-

Durability: GRP tanks are highly resistant to corrosion, making them ideal for storing potable water and other liquids.

-

Lightweight: Despite their strength, GRP tanks are lightweight, making them easier to transport and install compared to steel tanks.

-

Versatility: Available in various shapes and sizes, including GRP square shape tanks and sectional designs, GRP tanks can be customized to fit any space.

Conclusion

Proper installation of GRP tanks, whether GRP water tanks, FRP water tanks, or GRP sectional tanks, is essential for ensuring their longevity and effectiveness. By following the steps outlined in this guide, you can ensure a successful installation that will serve your needs for years to come. Regular maintenance and timely inspections will further enhance the performance of your GRP tank, making it a reliable solution for your water storage requirements.

Whether you are installing a GRP square shape tank for residential use or a large-capacity GRP sectional tank for an industrial application, attention to detail during installation and adherence to maintenance guidelines will pay off in the long run.